DESIGNING AND MANUFACTURING TRITIUM MANAGEMENT TECHNOLOGY.

tritium Collection systems: advanced modular reactor SMR

DESIGNING COMPLEX TRITIUM COLLECTION AND EXTRACTION SYSTEMS FOR ADVANCED REACTOR, SMR, NUCLEAR PLANT

MANUFACTURER OF TRITIUM COLLECTION SYSTEMS AND EXTRACTION PLANTS FOR ADVANCED SMALL MODULAR REACTOR SMR AND TRADITIONAL NUCLEAR PLANTS. FROM SMALL LABORATORY UNITS FOR TRITIUM LEVELS UP TO 1000 CI/L, TO DEMONSTRATION SCALE PLANTS WITH 1M³/H HYDROGEN THROUGHPUT, AND LARGE COMMERCIAL AND NUCLEAR FACILITY DETRITIATION APPLICATIONS DESIGNED FOR 150M³/H HYDROGEN THROUGHPUT.

Tritium Extraction and Heavy Water Upgrading

Tritium Extraction and Heavy Water Upgrading

Tritium Extraction and Heavy Water Upgrading

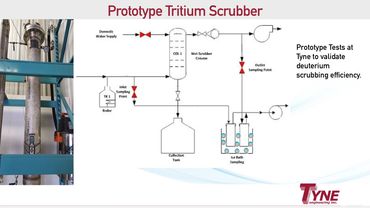

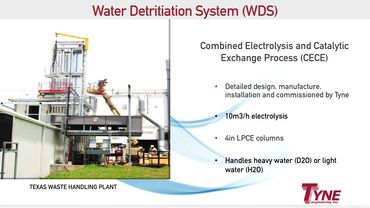

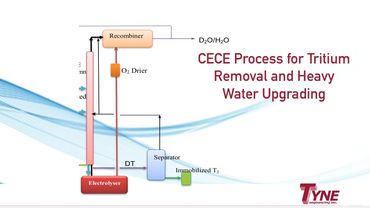

Specializing in tritium collection systems, Tyne Engineering has design built various sizes of tritium extraction plants and heavy water upgraders.

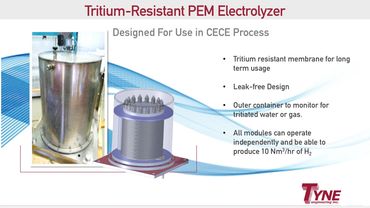

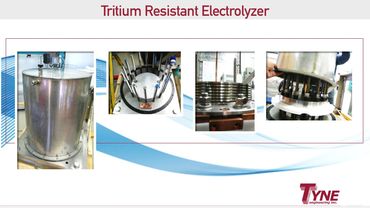

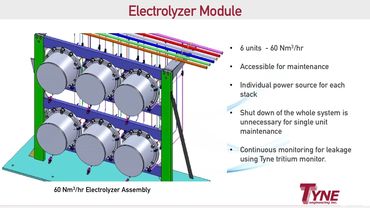

PEM Electrolyzers

Tritium Extraction and Heavy Water Upgrading

Tritium Extraction and Heavy Water Upgrading

Electrolysis is an essential part of the cycle of being able to remove tritium or separate hydrogen isotopes in light or heavy water or from organic materials. PEM Electrolyzers are used as part of the cycle for tritium removal.

Isotopic Separation Systems ISS

Isotopic Separation Systems ISS

Isotopic Separation Systems ISS

The isotopic separation system ISS separates tritium from deuterium and hydrogen. It can be used as the stage following electrolysis in the removal of tritium from heavy water or light water.

Pressure Vessels

Isotopic Separation Systems ISS

Isotopic Separation Systems ISS

Custom made tanks and pressure vessels with low leak integrity, high quality valves and fittings for tritium, nuclear, pharmaceutical, medical, experimental and oil and gas industry use.

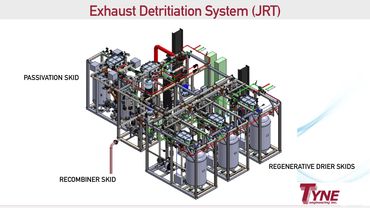

DETRITIATION: TRITIUM COLLECTION SYSTEMS

Tritium processes are exceptional in their variety, frequently applying a combination of cryogenics and relatively high temperatures and vacuum, or alternatively, high pressure. Tritium systems design involves measurement challenges, ultra low leakage, critical containment and custom storage solutions. Tyne Engineering is equipped with the expertise to customize the unique tritium system required for each customer.

25 years experience in:

- Tritium system design and manufacture

- Commissioning and site installation

- Cost control

- Project management and contract control

- Practical solutions to unique challenges

- Research and development

- Design studies

- Supplier selection, procurement, and auditing

- Receiving inspection and controlled storage

- Material control and traceability

- Document control for compliance with national and international standards

- ASME approved welding and NDE personnel certification

learn more

TRITIUM MONITOR DESIGNING, MANUFACTURING AND SUPPLYING TECHNOLOGIES

We are here to ensure our customers receive industry leading products and service.

Copyright © 2023 tyne usa - All Rights Reserved.

Phone: 1.877.969.TYNE or 1.877.969.8963 Fax: 1.877.715.5508 Email: sales@tyneusa.com