DESIGNING AND MANUFACTURING TRITIUM MANAGEMENT TECHNOLOGY.

TRITIUM COMPATIBLE PEM electrolyzer: ELECTROLYSIS hydrogen

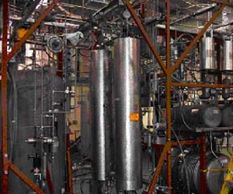

TRITIUM COMPATIBLE PEM electrolyzer FOR ELECTROLYSIS HYDROGEN TECHNOLOGY. Model: 7031-ELEC-001

OVER 30 YEARS DESIGNING AND MANUFACTURING TRITIUM COMPATIBLE PROTON EXCHANGE MEMBRANE PEM ELECTROLYZERS FOR PEM ELECTROLYSIS, AN ESSENTIAL PART OF THE CYCLE OF REMOVING TRITIUM OR SEPARATING HYDROGEN ISOTOPES IN LIGHT OR HEAVY WATER OR FROM ORGANIC MATERIALS. TYNE IS A LEADER IN THE DESIGN AND MANUFACTURING OF TRITIUM ELECTROLYSER TECHNOLOGY.

Proton Exchange Membrane PEM Electrolysis - Tritium Electrolyser Technology

PEM Electrolysis is an essential part of the cycle of being able to remove tritium or separate hydrogen isotopes in light or heavy water, or from organic materials.

- Tritium compatible Proton Exchange Membrane PEM electrolyzer is leak tight (10-8cc/sec helium or better)

- Safe (low pressure of less than 150 psig)

- Low inventory

- No pump or compressor required

- Hydrogen produced on demand

Electrolyzers are used as part of the cycle for tritium removal; electrolyzing water to obtain the gaseous hydrogen isotopes which can then be separated in an isotopic separation system. Conventional electrolyzers used for the production of hydrogen perform the process well, but need considerable modification to make then suitable for use with tritium. For example the piping system leak tightness is inadequate for a tritium electrolyser. The use of certain elastomers make it unsuitable. Vessels must be redesigned to meet the tighter requirements of tritium and the valves and fittings have to be upgraded. Tyne provides the tritium expertise required to modify electrolysers. Tyne provides the conceptual design, manufacture of the cell and the controls system, and sourcing of all valves and fittings.

The main concern of electrolysis of tritiated water is the longevity of the cell after being subjected to radiation.

Tyne designs and manufactures electrolysis cells producing 10 m^3 per day of hydrogen. Larger units can be produced.

Proton Exchange Membrane PEM. Unit designed for KHNP in Korea.

Tritium electrolyser modified for service by Tyne.

PEM electrolysis. Model 7031-ELEC-001.

learn more

Electrolyzer Model: 7031-ELEC-001

We are here to ensure our customers receive industry leading products and service.

Copyright © 2023 tyne usa - All Rights Reserved.

Phone: 1.877.969.TYNE or 1.877.969.8963 Fax: 1.877.715.5508 Email: sales@tyneusa.com