DESIGNING AND MANUFACTURING TRITIUM MANAGEMENT TECHNOLOGY.

Modular Detritiation System - Detritiation System design and Manufacturing

DETRITIATION PLANT: TRITIUM REMOVAL EXTRACTION SYSTEM DESIGN AND MANUFACTURING

A leader in modular detritiation system design technologies. Tyne has designed and manufactured complex tritium removal systems with applications worldwide. Tyne Engineering has design built various sizes of tritium extraction plants, from small laboratory units for tritium levels up to 1000 Ci/L, to modular detritiation design demonstration scale plants with 1m³/h hydrogen throughput, and large commercial and nuclear facility applications designed for 150m³/h hydrogen throughput.

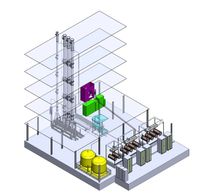

Modular Detritiation System Design and Manufacturing

Used in active waste facilities, research establishments, nuclear facilities and fusion laboratories for removing tritium from light or heavy water and concentrating into reduced volumes. The modular detritiation system design is useful for reducing stored volumes of tritiated water, or for use with an isotopic separation system for complete removal of tritium and safe storage on getter beds. The system can also be used for heavy water upgrading.

Tyne performs detailed design, manufacturing, and commissioning of key systems including gloveboxes using Tyne's proprietary tritium-compatible seals, tritium monitors and ion chambers using Tyne's own design, electrolyzer subsystem, oxygen hydrogen recombiners, exchange columns and control systems.

Tyne has co-authored a number of scientific papers on tritium extraction plants including large scale light water detritiation for the damaged facility at Fukushima Daiichi Nuclear Power Plant.

- Extract tritium from light or heavy water

- Upgrade heavy water

- Nuclear or commercial pressure code compliance

- Turnkey modular design and build solutions

- Automatic operation / Continuous process

- Low pressure and temperature

The Concentrator is a part of the system for removal of tritium from water. Purification is first required and achieved by electrolyzer conversion of water into hydrogen and oxygen gases. The hydrogen, containing the tritium, is then passed through the Concentrator. Tritium rising with the hydrogen isotopes within the Concentrator columns is transferred to descending water, forming high concentrations in the bottoms water, releasing tritium-free hydrogen. Tritium concentration is readily increased by 1,000 times or greater.

In the case of heavy water, the released deuterium gas will be recombined with oxygen to produce clean, upgraded heavy water.

Further treatment involves recirculating the concentrated tritiated water through the electrolyzer, and separating tritium from the gaseous hydrogen isotopes in an Isotopic Separation System. The isolated tritium can then be stored safely on getter beds.

Tyne has manufactured 37.5 mm dia and 100 mm dia columns for both light and heavy water. The stainless steel columns are different lengths depending on the degree of separation required. The column pumps, valves and automatic controls are operated from a glovebox located at the base of the columns.

Tyne can provide turn-key tritium extraction or heavy water upgrading solutions.

150m³/h hydrogen, 600Mg/annum Light Water Detritiation System designed to Nuclear Standards.

LPCE columns designed and fabricated by Tyne Engineering.

Oxygen Hydrogen recombiners, designed and built by Tyne Engineering are used in some configurations.

learn more about tritium removal technologies

Tritium Extraction and Heavy Water Upgrading

We are here to ensure our customers receive industry leading products and service.

Copyright © 2023 tyne usa - All Rights Reserved.

Phone: 1.877.969.TYNE or 1.877.969.8963 Fax: 1.877.715.5508 Email: sales@tyneusa.com