DESIGNING AND MANUFACTURING TRITIUM MANAGEMENT TECHNOLOGY.

tritium monitoring system technology design and manufacturing

Model: 7042

features

Tyne's Multi Room Tritium Monitoring: Model 7042 is tritium monitoring technology capable of simultaneously monitoring up to 32 remote locations or rooms for background (environmental, gamma and other isotopes) compensated tritium activity. It is suitable for use in nuclear power stations, tritium extraction plants, laboratories or any location where tritium contamination is possible.

- 32 Detection Points

- 2 minute minimum measurement time

- 1 µCi/m³ sensitivity

- Zero maintenance drier to compensate for other isotopes

- Compensates for Gamma, environmental effects, and plate out

- Microprocessor controlled

- Front End GUI (General User Interface)

- Display curves for each room

- 12 month data accumulation

- Two alarm settings

- Easy access dust filter

- Rooms and sampling frequency is selectable

- Control or transfer data over Ethernet connection

The tritium monitoring system will automatically proceed with a selectable sequence of room measurements with a minimum required measurement time of 2 minutes. The system uses a zero maintenance drier with dew point measurements to calculate the background contribution from gamma radiation, other radio nuclides and any offsets from the total signal. This ensures that the system only measures the amount of tritium in the HTO form. The computer control, automatic filter cleaning and zero maintenance drier allows the system to operate maintenance free throughout the year. All data is logged and charted and can be accessed remotely by Health Physics. This automated solution for multi room tritium air monitoring ensures that all data is recorded without any human errors involved.

Tritium-in-Breath Monitor

Model: 7008

features

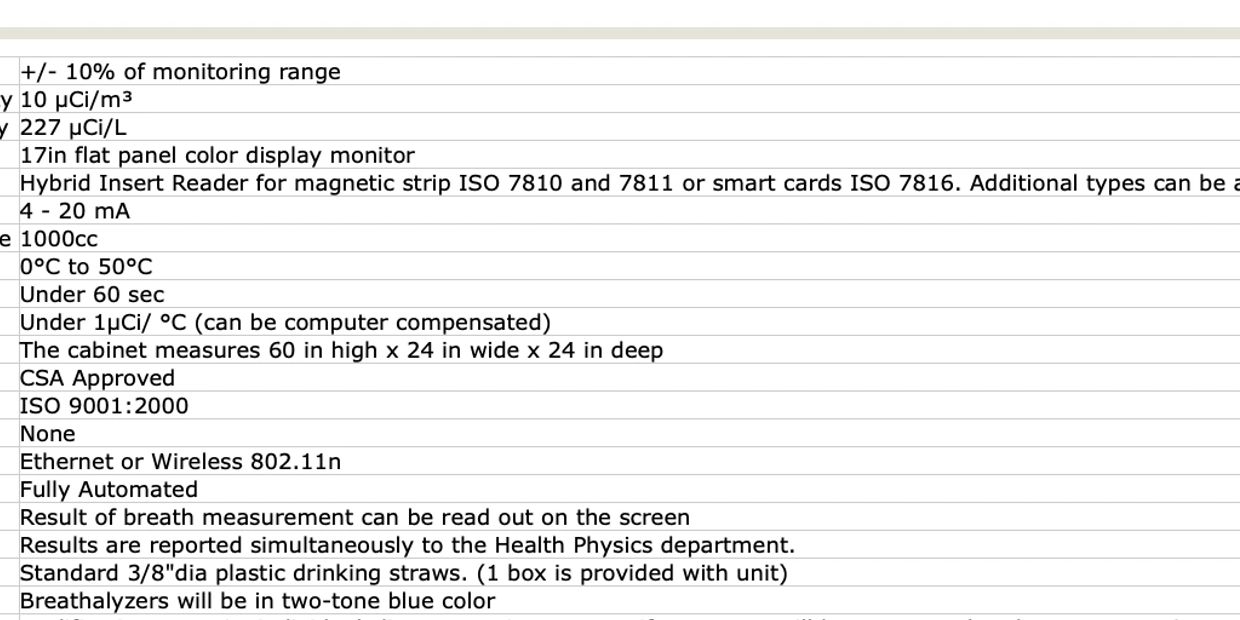

The Tritium In Breath Monitor: Model 7008 is intended to simplify measuring bodily intake of high levels of tritium in persons who have been working in areas where the release of tritium is possible. This tritium monitoring technology is a great addition to the current method of urine analysis because the results are discovered immediately.

- Easy and convenient to use

- No specialty gases required

- Quick operation (between 15 seconds and 1 minute)

- Reports tritium-in-breath results by e-mail to operator and Health Physics simultaneously

- Auto corrects for all background influences

The tritium-in-breath analyzer is housed in a kiosk that can be located conveniently for operators leaving areas of potential tritium contamination. It enables them to acquire an immediate measure of bodily uptake of tritium, and simultaneously informs Health Physics so that rapid preventive and corrective action can be taken in the event of high uptake.

The tritium breathalyser utilizes a large (3 liter) ion chamber to maximize sensitivity while minimizing the time taken to fill with exhalation. It is compensated for gamma and background radiation by the provision of a second and identical chamber. The chamber itself is of wire cage construction, designed for minimum surface area and reduced plate-out.

The tritium breathalyzer uses ionization chamber technology which requires no specialty gases to operate. The computer controlled measurement compensates for background gamma radiation and any other environmental offsets. Operators working in potentially contaminated areas swipe their identification card at the breathalyzer kiosk to initiate operation, select a "straw" from a dispenser mounted on the side of the kiosk and push it into an orifice on the front face of the kiosk. The operator then blows into the straw. Once the instrument has analyzed the breath an "All Clear" or "Visit Health Physics" message is displayed. The results are simultaneously emailed to Health Physics for record keeping. Typical time between processing of personnel is 30 - 60 seconds.

This tritium monitoring system is a great addition to the current system of urine analysis. While urine analysis may take up to 2 weeks to receive the results, the breathalyzer gives results of high level activities immediately. Health Physics can then respond quickly to the problem ensuring that the worker is properly treated and that no other workers are exposed by the same incident.

more about tritium monitoring

Tritium in Air Monitoring

Tritium in Process Tubing Monitoring

Tritium Surface Monitoring

Tyne Engineering has designed and manufactured a wide range of tritium air monitors. Our products can be incorporated into customized tritium management system design requirements. Applications include:

- Medical

- Academic & scientific

- Industrial

- Nuclear power plants

Tritium Surface Monitoring

Tritium in Process Tubing Monitoring

Tritium Surface Monitoring

Tyne offers expedited delivery of two of their popular surface activity monitors:

- Model 7001 works with flat or uneven surfaces by utilizing smear paper

- Model 7019-SWTM-001 monitors soft waste such as paper, towels, clothing

Tritium in Process Tubing Monitoring

Tritium in Process Tubing Monitoring

Tritium in Process Tubing Monitoring

Tyne Engineering has developed instruments specifically for measuring tritium inside process lines. Applications include:

- Tritium handling systems

- Getter bed loops

- Tritium lights manufacturing

- Laboratory experimentation

- Drug labeling systems

learn more

Copyright © 2023 tyne usa - All Rights Reserved.

Phone: 1.877.969.TYNE or 1.877.969.8963 Fax: 1.877.715.5508 Email: sales@tyneusa.com