DESIGNING AND MANUFACTURING TRITIUM MANAGEMENT TECHNOLOGY.

Preamplifier Purging equipment 1000 cc

Model: 7005-PAP1000-001

features

The Preamplifier Purging Equipment is intended to purge the preamplifier in potentially explosive situations and to cool the unit in situations where the electronics of the preamplifier may get too hot.

- Can be mounted outside of a glove box.

- Can be adjusted to control the flow or the pressure in a preamplifier.

Tyne Engineering's tritium monitors can be safely used in explosive environments provided adaptation is made for a purging unit. This will permit access of a dry inert gas (nitrogen, argon or helium) to flow through the preamplifier thereby excluding air therefore eliminating the opportunity for the formation of explosive mixtures. The preamplifier can be sealed sufficiently well to maintain a slight positive pressure inside the preamplifier. The purging unit is also recommended to cool the preamplifier if it operates in an environment of more than 50°C.

The equipment utilizes an aluminum adaptor flange fitted between the ion chamber and the preamplifier. Inlet and outlet tube connections are also attached to the adaptor flange and some additional tubing inside the preamplifier directs the inert gas to flush and exclude air from the preamplifier.

The inert gas is supplied by a small purging/pressurization system suitable for purging volumes of up to 2 cubic feet. The purging unit is suitable for class 1 applications (flammable gases or liquid vapors). The unit supplied does not have a pressure switch, but comes with a pressure regulator and a pressure gauge. The purging unit is attached to a stainless steel plate for universal mounting.

The operator must ensure a continuous supply of inert gas to the purging unit, and to ensure that pressures in the preamplifier do not exceed 125 mm water gauge.

The purging unit measures 229 mm x 229 mm x 122 mm.

Outside dimensions are: 4.82” (122mm x 9” (228 mm) x 5.22” (133 mm).

Calibration Kit for Tritium Measurement Equipment

Model: 7500-CKIT-001-C

features

The Calibration Kit is a perfect solution for the yearly calibration of tritium monitoring equipment. The kit contains all the equipment necessary to electronically calibrate the tritium controller and the preamplifier. The kit includes all the equipment, cabling and documentation to carry out onsite calibration.

- NIST calibrated voltage source, current injection resistors, and volt meter

- Cable to inject calibrated voltage into the controller

- Preamplifier power box for calibration without a controller

- Easy to follow instructions

- Calibration forms and stickers

The ionization chamber is a fixed volume and does not need to be calibrated yearly but the electronics that measure the femto-amp current can change over time. Therefore, yearly calibration of all the electronics in a tritium monitoring system is recommended.

The calibration kit has been designed to make this process simple and efficient. Each part of the tritium monitoring system can be calibrated independently. The preamplifier can be removed from the ionization chamber and taken to a separate room where it can be powered by the preamplifier power box and calibrated with the voltage source, calibrated resistors and voltmeter. The power box will also allow manual switching of the preamplifier ranges. The tritium controller can be calibrated on site using the calibrated voltage source, volt meter and the voltage injection cable.

All calibration data is entered onto an easy to read calibration form. The information is then entered into the supplied data base which will generate a properly formatted calibration report. The supplied stickers can be filled out and then applied to the equipment.

All calibration equipment and documentation is carried in a rugged plastic case for in-field work.

Single Range Tritium Signal Processor Kit

Model: 7501-TSPKIT-001-C

features

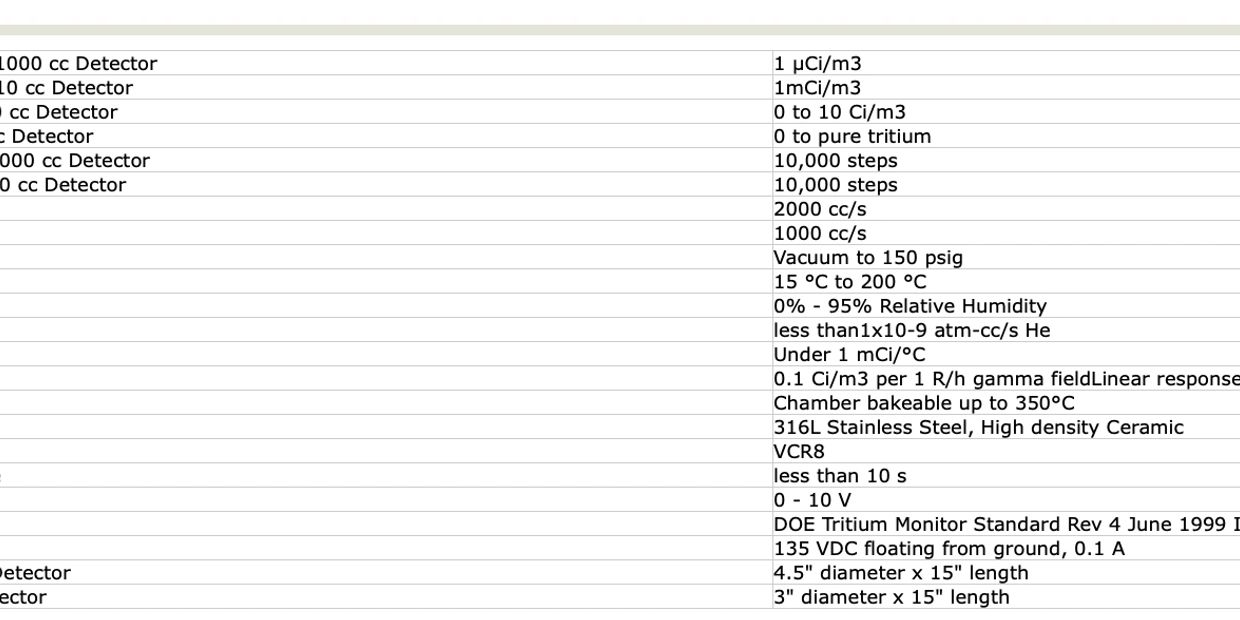

The Single Range Tritium Signal Processor measures the amount of tritium directly in line of a process loop in real time and transmits a 0 – 10V output signal. The unique small footprint detector head has the ability to handle up to 150 psig. It is leaktight and can operate at elevated temperatures. Up to 10 transmitters may be powered by one low cost power supply making this the most cost effective solution for a process with many detection locations.

- Direct inside process line installation

- Low sensitivity of 1 µCi/m³

- 150 psig Pressure vessel

- Operates at temperatures above 100°C

- Leak tight to 1x10-9

- 0 – 10 V output for integration into data systems

- User selectable scale of up to 10,000 units

- Low cost

The Single Range Tritium Signal Processor is the most cost effective solution for measuring multiple locations in a process loop in real time. The detector and transmitter are packaged into a single small footprint device that can be located directly inline with your process. Only the power line, which can daisy chain up to 10 units, and the BNC voltage output are needed to measure the activity in your process. The Single Range Tritium Signal Processor is user selectable between 1µCi/m³ to 10,000 kCi/m³ with 10,000 measurement steps. For example one unit can measure from 1 µci/m³ to 10,000 µCi/m³ while the second unit in the line can measure from 10 mCi/m³ to 100 Ci/m³. The measurement signal is mapped to a voltage output from 1 mV to 10,000 mV which can be measured by a simple volt meter or incorporated into a 16 bit data acquisition system.

learn more

Copyright © 2023 tyne usa - All Rights Reserved.

Phone: 1.877.969.TYNE or 1.877.969.8963 Fax: 1.877.715.5508 Email: sales@tyneusa.com